Quality First, Customers First

Colame prioritizes production of the products that meet the needs of the market, and ensures that the produced products achieve the consistent goal of safety.

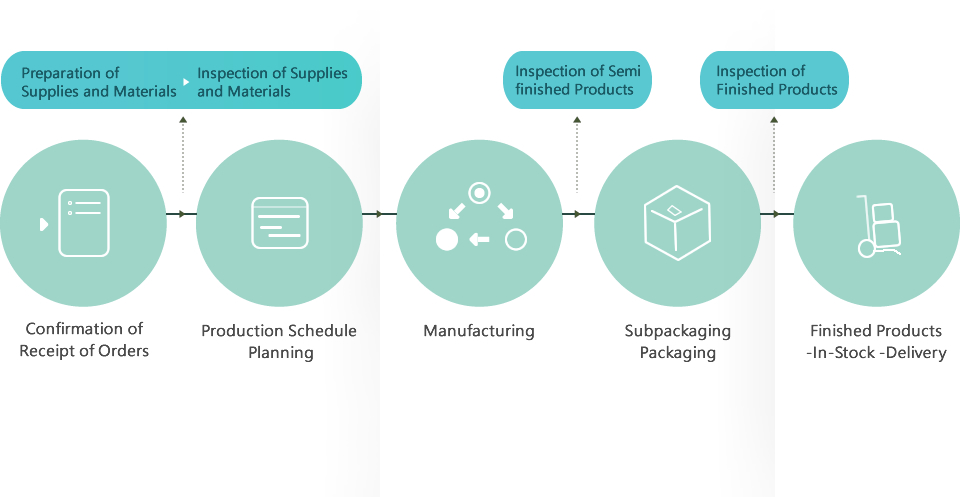

Safe cosmetics is a very common and important issue. The production factory of Colame Cosmetics Co., Ltd. thoroughly implements qualitative and quantitative management of products. From selection and procurement of each raw material (including the supplies of customers) to batch production, each detail of the entire process must implement strict inspection. All the colleagues of Colame wholeheartedly put efforts on producing safe and reassuring products, and controlg the quality and quantity of products.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)